Lapping

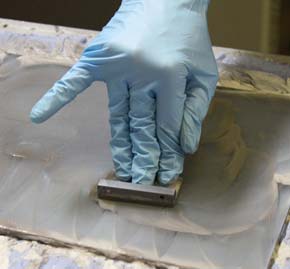

When the silicon has been machined or ground to shape it has significant stress in the surface of the material. This stress is removed by the process of lapping. This is a process in which the machined part is rubbed against another surface with an abrasive between them. For small items this process can be done by hand as shown on the right.

Larger items such as long x-ray mirrors are lapped on large machines that we have designed ourselves. These move slowly, using an abrasive slurry, to lap the surface to be flat or curved as required. It is a slow process and can take weeks for a large mirror.